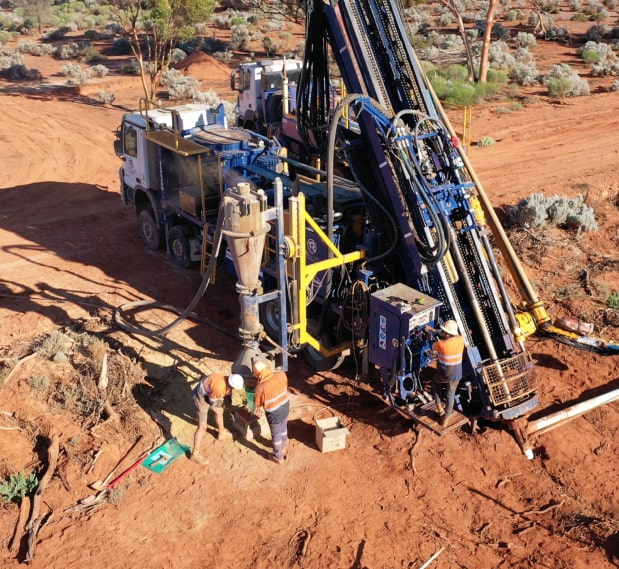

Acquired in 2023, the Mount Dimer site is Beacon Minerals’ most remote location. Beacon Minerals needed a reliable contractor to conduct exploratory drilling without supervision, with the competency to deliver quickly.

The team was impressed with Raglan Drilling’s speed, competency and commitment to safety. When mechanical issues threatened timelines, Hugh flew the replacement parts to the site, bringing the project back on track without losing significant time.

“Raglan Drilling’s expertise and commitment to safety made them an easy choice for our remote Mt Dimer project.”